WORKBENCH WORK SURFACES

Machlab offers a variety of work surface options for any industrial application. These materials are tested and finished to the highest quality. Available for use as worktops and shelving materials in standard or custom dimensions to meet your requirements.

Our representatives will be happy to discuss the benefits of each surface and assist you in selecting the right material that matches your application, working condition and budget requirement.

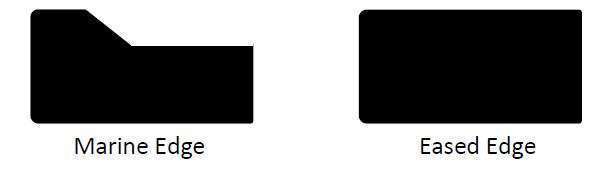

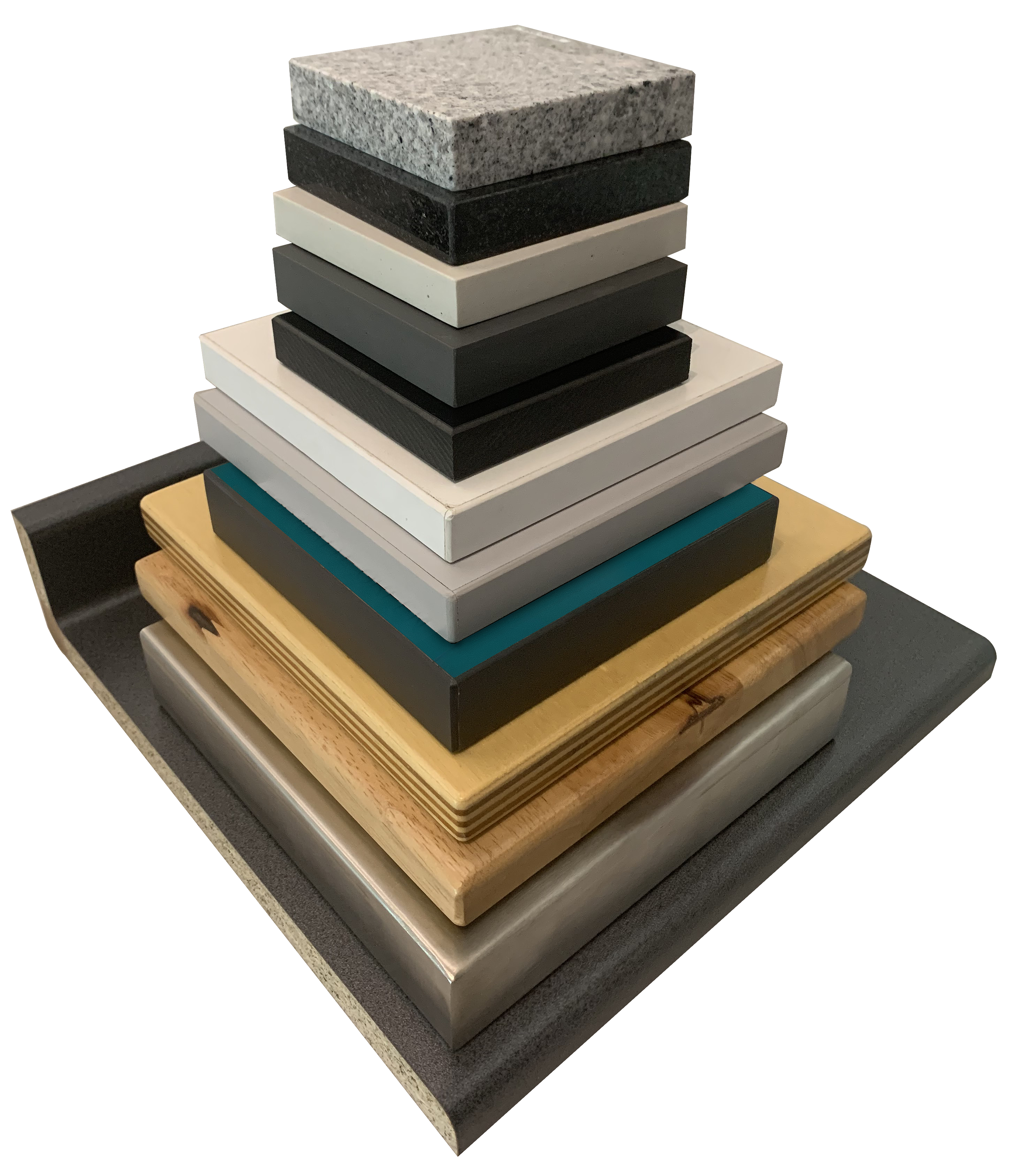

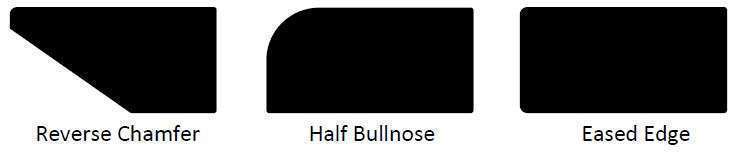

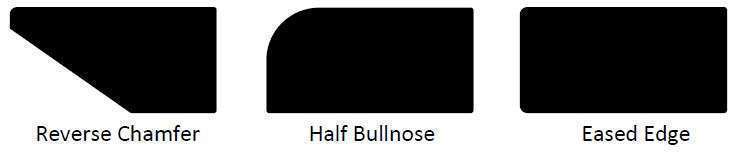

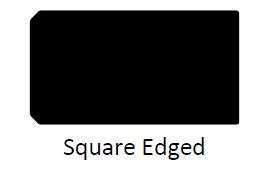

Melamine Faced Chipboard (MFC)

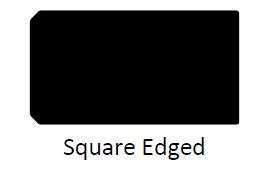

Consist of wood chips bonded together with melamine laminate surface finish. The standard thickness in the industry is 25mm. The finishing comes with 1.0mm ABS edge band protection against accidental bumps or scrapes. Moderate strength and not suitable for wet area. An economical option ideal for light-duty work.

Solid Plywood

High impact resistance due to its tensile strength, making it strong and stable when used as worktop. Good uniform strength and durability. Moderate water resistance. Ideal for mechanical workshops. Resin-based natural varnish ensures an impervious protective coating that is hardwearing and enhances the aesthetics at the same time. Comes in standard eased edge profile.

Rubberwood

Resilient hardwood that is perfect for withstanding wear and tear. Made by joining individual staves to form a very solid and strong worktop, which makes it suitable for heavy-duty works. Environmentally friendly – harvested from latex-depleted plantation rubber trees and does not contribute to deforestation. Resin-based natural varnish ensures an impervious protective coating that is hardwearing and enhances the aesthetics at the same time. Comes in standard eased edge profile.

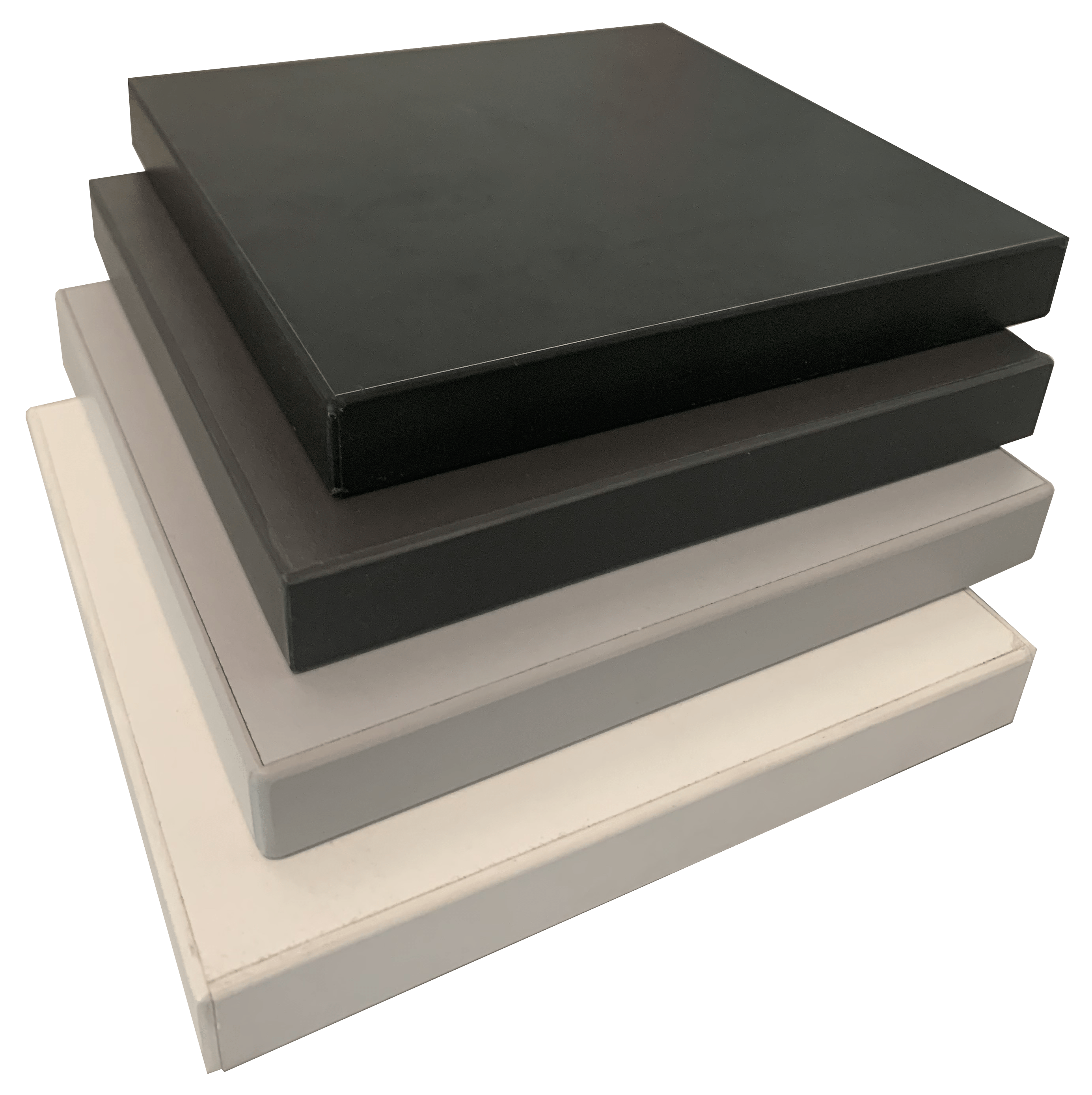

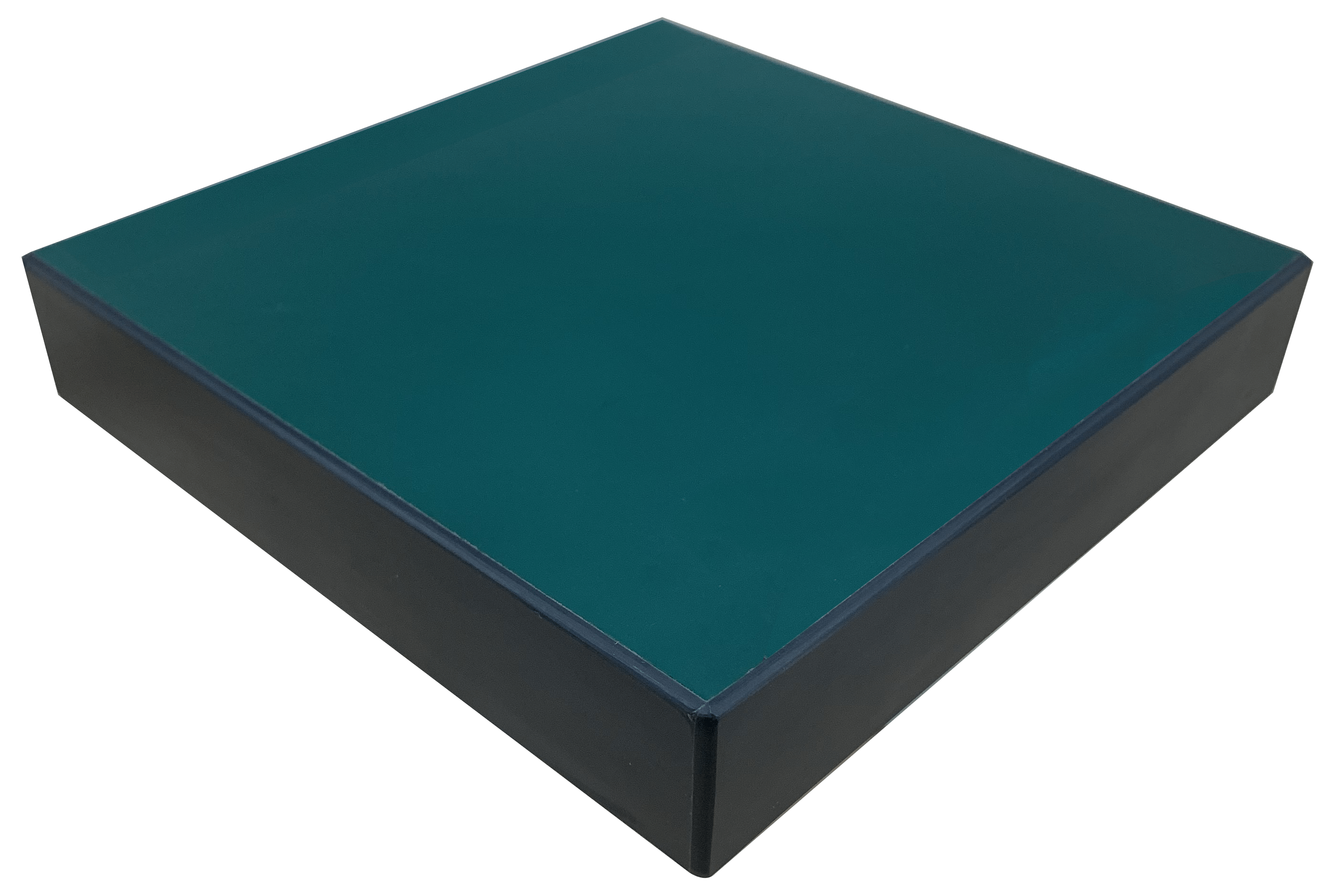

MACH-ESD Worksurface

Available in Green, Blue and Grey colours.

Stainless Steel

Machlab Stainless Steel worktops are fabricated of 16-gauge, Type 304 or 316 with a #4 finish. All corners, open ends and joints are continuously welded and ground smooth. Box channel reinforcements are welded on the underside of the worksurface. Optional sound-deadening material is applied to the underside. Stainless steel sink bowls and cup sinks are integrally welded into the top, providing a joint-free assembly.